H Series Bus Diesel Engine

With advanced design concept from Europe and America fully absorbed, this H series bus diesel engine is a new generation of product that is energy saving and eco-friendly. Due to the combination of advanced 4 valves technology, cracking connecting rod, lightened production and other technologies, the product is adequate to fulfill the emission requirements of current China IV standard and the China V standard in the future.

Integrated with the frontier technology of the internal combustion engine currently in the world, this H series bus diesel engine owns such features like fuel conservation, large power, excellent reliability, low noise and other advantages. It works as the ideal power support of the middle and large sized passenger vehicles.

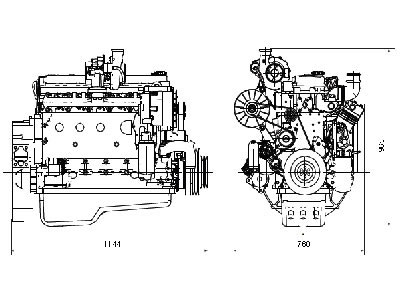

SC7H Diesel Engine

| Model | Unit | EURO III, Euro III/Euro IV, Euro V | ||||||

| SC7H180 | SC7H200 | SC7H215 | SC7H220 | SC7H230 | SC7H245 | SC7H260 | ||

| Type | 6 in-line cylinders, electronic controlled common rail, 4-valve, dry cylinder liner, 4-stroke, water cooling, rear gear housing | |||||||

| Aspiration | TCI | |||||||

| Bore ×Stroke | mm | 105×124 | ||||||

| Total displacement | L | 6.5 | ||||||

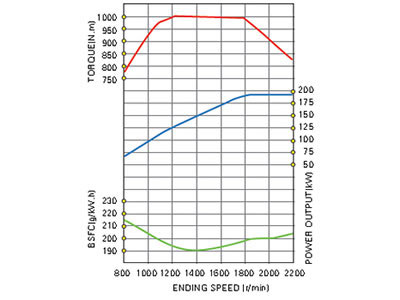

| Rated power/rated speed | kw/r/min | 132/2300 | 147/2300 | 158/2200 | 162/2500 | 170/2300 | 180/2300 | 192/2300 |

| Min. fuel consumption | g/kw.h | ≤190 | ||||||

| Maximum torque/speed | N.m/r/min | 660/1200 ~1600 | 750/1200 ~1600 | 900/1200 ~1600 | 800/1200 ~1600 | 900/1200 ~1600 | 960/1200 ~1600 | 1000/1200 ~1600 |

| Noise | dB(A) | ≤95 | ||||||

| Weight | kg | 520 | ||||||

| Power range | ps | 180~260 | ||||||

| Technology | Function | Advantage |

| 4 valves are mounted in every cylinder and the fuel injector is laid vertically in the middle. | Increase the inlet flow and get the atomized fuel distributed reasonably | Improve the engine performance like horsepower and torque and reduce the fuel consumption. |

| Latest generation of Nippon Denso HP3 fuel system with high pressure common rail | The maximum fuel injection pressure reaches 1800bar, which may lead to excellent fuel atomization. The flow deviation of the fuel injector is controllable. | Low emission, noise and fuel consumption. |

| Modular integration design,the engine is integrated with the oil cooler cavity, water pump casing, oil pump cavity and other parts. | The quantity of the parts and the sealing surface are decreased. | The reliability of the H series bus diesel engine is improved. |

| Integral cylinder cover and the high strength engine with reinforcing rib in patent design | Excellent rigidity of the entire engine | Low vibration and noise |

| Cracking connecting rod | The upper cover of the connecting rod matches the lower cover one for one to avoid errors and keep good alignment. | Easy repair and maintenance |

| Dry cylinder liner | The cylinder liner material may have better performance than that of the engine block. | Improve the abrasive resistance and the engine is easier for repair and maintenance than the product without cylinder liner. |

| Aluminum piston with corrugated inner cooling oil passage | The cooling effect of the piston is greatly improved | The operation reliability of the piston is increased. |

| International leading Nippon Denso ceramic chip ECU | Low heat dissipation requires no external cooling pipeline | High reliability of the whole engine |

| High pressure fuel pipeline made of imported dual layers of metal materials of Japan | Excellent resistance to pressure and the corrosion | Reliable fuel pipeline |

| Peripheral accessories in standardized design | Exchangeable with the mainstream accessories, making the accessories easily available. | Easy repair and maintenance |

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی